Advanced Materials and Physics Division

Developing advanced superconducting materials and improving the performance of coated conductors (CCs) through the clarification of their peculiar properties

Purpose of research

- Because of the complex composition and structure as well as the large anisotropic physical properties of the cuprate high-temperature superconductors, there are still several unsolved problems for practical application of coated conductors (CCs) based on the cuprate superconductors to power devices, such as in their in-field properties, uniformity, and structural stability against processing. The aim of the Advanced Materials & Physics Division is to develop advanced superconducting materials that possess superior in-field properties based on the advanced characterization techniques for basic material properties as well as inspection of CCs. We also support realization of practical use of CCs,through the developments of multi-filamentarization and repairing techniques.

Research themes

- Search for advanced superconducting materials with higher irreversibility field

- Understanding of flux pinning mechanism and development of superconducting materials with higher Jc in magnetic fields

- Development of characterization methods for coated conductors (CCs) and testing method of long-term stability

- Developments of reliable filamentarization process, joint and repair process for CCs

Major results

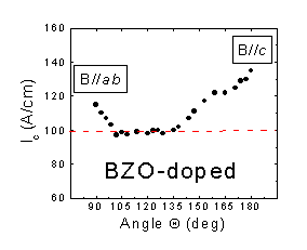

- Development of 5 μm thick BZO-doped GdBCO films on IBAD-GZO with high Ic by in-plume PLD

|

Configuration of in-plume PLD (left) and angle dependence of Ic in 3 T field at 77 K (minimum Ic is as high as 100 A/cm-w). |

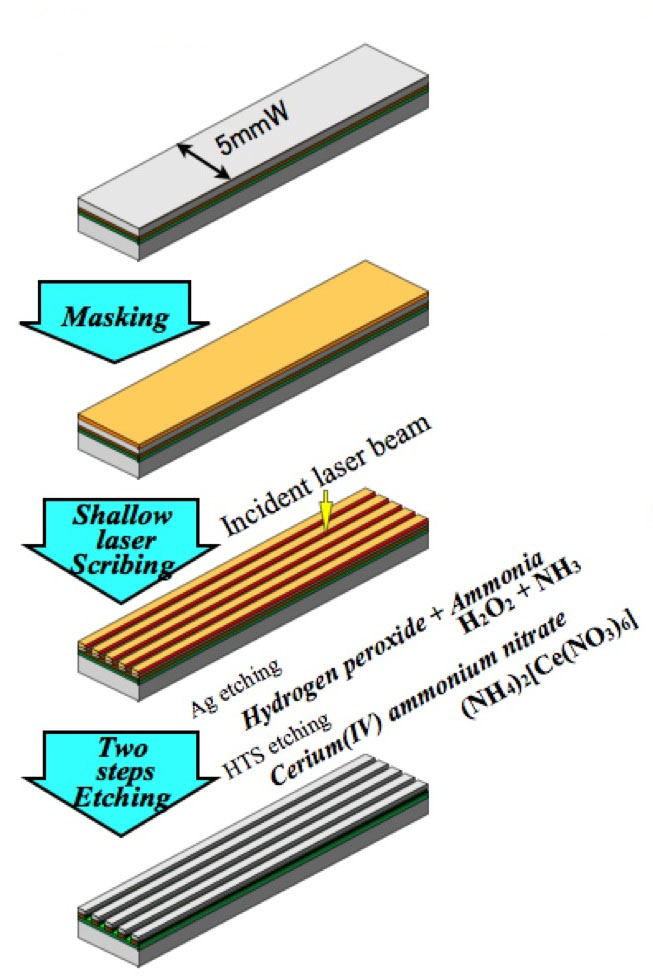

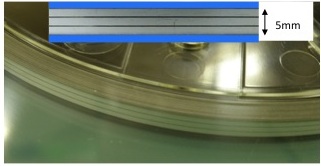

- Development of reel-to-reel filamentarization (striation) process for coated conductors with low AC loss

|

Optical photograph of 30 m-long and 5 mm-wide coated conductors with three filaments fabricated by laser scribing and chemical etching methods.  I-V curves of each filaments fabricated by the laser scribing method. |

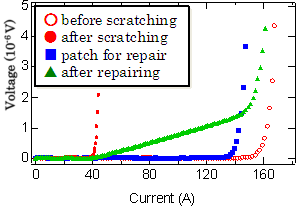

- Development of Ag diffusion joint process for repair of CCs

|

Current-voltage characteristics before and after repairing. |

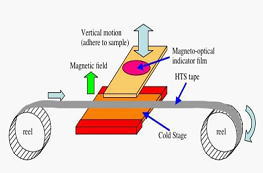

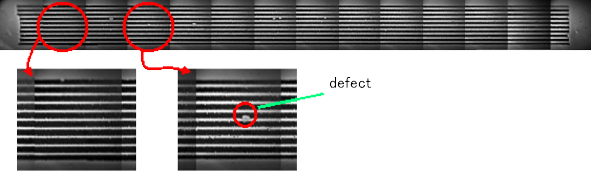

- Development of reel-to-reel magneto-optic (MO) imaging system for CCs

Schematic illustration (up) and picture (right) of reel-to-reel MO imaging system |

|

MO images for multi-filamentary CCs. |

Major Contributions

- Development of higher-performance (low AC loss, high yield) coated conductors

- Development of power equipments such as SMES, cables and transformers.

- Development of equipments for use in high magnetic fields such as motors and MAGLEV

Key papers

- S.Lee, N. Chikumoto, T.Yokoyama, T.Machi, K.Nakao, K.Tanabe, "Development of In-Plume Pulsed Laser Deposition of High-Ic GdBCO Films for Coated Conductors", IEEE Trans. Appl. Supercond. 19, 3192-3195 (2009) .

- J. Kato et al., “Optimization of the diffusion joint process for the Ag layers of YBCO coated conductors”, Physica C 463-465, pp. 747-750 (2007).

- K. Nakao et al., “Non-destructive characterization of long coated conductors using a Hall sensor array”, Physica C 445-448, pp. 669-672 (2006).

- T. Machi et al., “Development of a magneto-optical imaging equipment for long length 2G-HTS tapes”, Physica C 445-448, pp. 673-676 (2006).